English

T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

| Availability: | |

|---|---|

| Quantity: | |

Product Advantage

Improved Efficiency:

The carton sealing machine, including both automatic tape machines and carton sealers, can significantly enhance production efficiency by replacing manual sealing operations. This automation allows for faster sealing speeds and adjustable specifications, optimizing the packaging production line.

Reduced Labor Intensity:

By utilizing automatic carton sealers, the physical strain on workers is minimized. These machines eliminate the discomfort and fatigue associated with long-term repetitive manual labor, resulting in a more productive workforce.

Cost Savings on Labor:

Investing in carton tape sealing machines can lead to substantial savings in labor costs over time. These automated systems prove to be more reliable and economical than manual labor, with relatively low maintenance costs, making them a smart long-term investment.

Strong Adaptability:

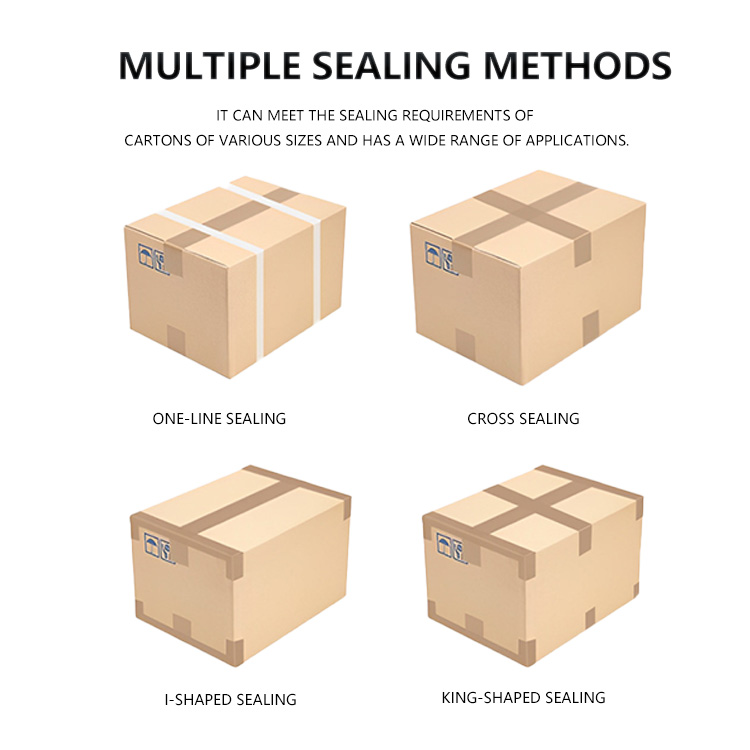

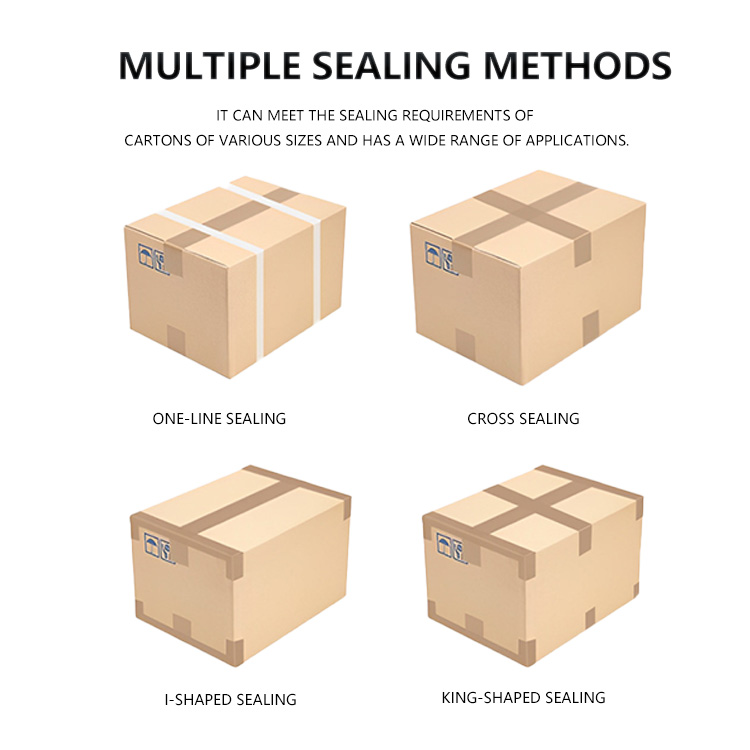

Carton sealers and automatic box sealing machines are designed to accommodate cartons of various specifications and sizes. Their customizable design allows for integration into existing production lines, ensuring they meet the unique needs of any operation.

Quality Assurance:

The sealing quality provided by automatic box sealing machines is consistently high, reducing the risk of loose seals caused by human error. This reliability ensures that products are securely sealed, enhancing overall packaging integrity.

Seamless Integration with Other Equipment:

The box strapping machine can be easily integrated with carton sealing machines, allowing for a complete packaging solution. This synergy enhances the overall workflow and efficiency of the packaging process.

User-Friendly Operation:

Many carton sealing machines feature intuitive controls, making them easy to operate for staff. This simplicity reduces the learning curve and enables quick adjustments to meet production demands.

Enhanced Production Output:

The automation provided by carton sealing machines can significantly increase the number of cartons sealed per hour compared to manual processes, leading to faster turnaround times and improved overall output.

In summary, the carton sealing machine offers a range of advantages, including increased efficiency, reduced labor intensity, cost savings, adaptability, and quality assurance, making it an essential asset for modern packaging operations

Technical Parameters

Conveying speed 5 boxes/minute

Maximum packaging size L600×W500×H500mm

Minimum packaging size L200×W150×H150mm

Power supply 220/380V, 1∮-3∮, 50-60Hz

Power consumption 400W

Applicable tape W48mm/60mm/75mm (choose one to use)

Machine size L2460×W1420×H1650mm

Machine weight 350kg

Product Uses

Logistics and express delivery industry: In the logistics and express delivery industry, cartons are one of the most commonly used packaging materials. By using a carton unpacking and sealing machine, the packaging process can be completed quickly, saving storage space and time costs, and improving work efficiency.

Electronics industry: The production line of electronic products requires frequent product packaging and transportation. The use of carton unpacking and sealing machines can achieve accurate and fast packaging operations, effectively protecting the safety and integrity of products during transportation.

Food processing industry: Food processing plants often need to pack raw materials or finished products into cartons for storage and transportation management. By applying this equipment, the hygiene and safety of food can be ensured and the error rate of manual operations can be reduced.

Product Operate Guide

Preparation before starting

Before using the fully automatic carton sealer, please ensure that the equipment is placed stably, the surrounding environment is clean, and there is no interference from debris. Check whether all parts of the equipment are intact, whether the conveyor belt is properly tensioned, and whether the power supply is connected normally. Prepare the goods to be sealed and ensure that the size of the goods is compatible with the carton sealer.

Start the equipment

Connect the power supply and turn on the power switch of the fully automatic carton sealer. At this time, the equipment enters the standby state. Adjust the speed of the conveyor belt as needed to meet the requirements of different carton sealing speeds.

Place the goods

Place the goods to be sealed on the conveyor belt to ensure that the goods and the conveyor belt move forward synchronously. The placement of the goods should be kept stable to avoid tilting or collapse during transportation.

Adjust the sealing device

Adjust the position of the upper and lower tapes of the sealing device according to the size of the goods and the sealing requirements. Ensure that the tape can fit the surface of the goods tightly, and avoid being too tight or too loose to cause poor sealing effect.

Start sealing

When the goods enter the sealing area, the fully automatic carton sealer will automatically perform the sealing action. The sealing device will stick the upper and lower tapes to the surface of the goods and heat-seal the tapes through the electric heating wire. After the heat sealing is completed, the device will automatically cut the tapes to complete the sealing process.

Collect the sealed goods

The sealed goods will continue to move along the conveyor belt and eventually be discharged from the equipment outlet. Please collect the sealed goods in time to avoid long-term accumulation on the equipment

Product Advantage

Improved Efficiency:

The carton sealing machine, including both automatic tape machines and carton sealers, can significantly enhance production efficiency by replacing manual sealing operations. This automation allows for faster sealing speeds and adjustable specifications, optimizing the packaging production line.

Reduced Labor Intensity:

By utilizing automatic carton sealers, the physical strain on workers is minimized. These machines eliminate the discomfort and fatigue associated with long-term repetitive manual labor, resulting in a more productive workforce.

Cost Savings on Labor:

Investing in carton tape sealing machines can lead to substantial savings in labor costs over time. These automated systems prove to be more reliable and economical than manual labor, with relatively low maintenance costs, making them a smart long-term investment.

Strong Adaptability:

Carton sealers and automatic box sealing machines are designed to accommodate cartons of various specifications and sizes. Their customizable design allows for integration into existing production lines, ensuring they meet the unique needs of any operation.

Quality Assurance:

The sealing quality provided by automatic box sealing machines is consistently high, reducing the risk of loose seals caused by human error. This reliability ensures that products are securely sealed, enhancing overall packaging integrity.

Seamless Integration with Other Equipment:

The box strapping machine can be easily integrated with carton sealing machines, allowing for a complete packaging solution. This synergy enhances the overall workflow and efficiency of the packaging process.

User-Friendly Operation:

Many carton sealing machines feature intuitive controls, making them easy to operate for staff. This simplicity reduces the learning curve and enables quick adjustments to meet production demands.

Enhanced Production Output:

The automation provided by carton sealing machines can significantly increase the number of cartons sealed per hour compared to manual processes, leading to faster turnaround times and improved overall output.

In summary, the carton sealing machine offers a range of advantages, including increased efficiency, reduced labor intensity, cost savings, adaptability, and quality assurance, making it an essential asset for modern packaging operations

Technical Parameters

Conveying speed 5 boxes/minute

Maximum packaging size L600×W500×H500mm

Minimum packaging size L200×W150×H150mm

Power supply 220/380V, 1∮-3∮, 50-60Hz

Power consumption 400W

Applicable tape W48mm/60mm/75mm (choose one to use)

Machine size L2460×W1420×H1650mm

Machine weight 350kg

Product Uses

Logistics and express delivery industry: In the logistics and express delivery industry, cartons are one of the most commonly used packaging materials. By using a carton unpacking and sealing machine, the packaging process can be completed quickly, saving storage space and time costs, and improving work efficiency.

Electronics industry: The production line of electronic products requires frequent product packaging and transportation. The use of carton unpacking and sealing machines can achieve accurate and fast packaging operations, effectively protecting the safety and integrity of products during transportation.

Food processing industry: Food processing plants often need to pack raw materials or finished products into cartons for storage and transportation management. By applying this equipment, the hygiene and safety of food can be ensured and the error rate of manual operations can be reduced.

Product Operate Guide

Preparation before starting

Before using the fully automatic carton sealer, please ensure that the equipment is placed stably, the surrounding environment is clean, and there is no interference from debris. Check whether all parts of the equipment are intact, whether the conveyor belt is properly tensioned, and whether the power supply is connected normally. Prepare the goods to be sealed and ensure that the size of the goods is compatible with the carton sealer.

Start the equipment

Connect the power supply and turn on the power switch of the fully automatic carton sealer. At this time, the equipment enters the standby state. Adjust the speed of the conveyor belt as needed to meet the requirements of different carton sealing speeds.

Place the goods

Place the goods to be sealed on the conveyor belt to ensure that the goods and the conveyor belt move forward synchronously. The placement of the goods should be kept stable to avoid tilting or collapse during transportation.

Adjust the sealing device

Adjust the position of the upper and lower tapes of the sealing device according to the size of the goods and the sealing requirements. Ensure that the tape can fit the surface of the goods tightly, and avoid being too tight or too loose to cause poor sealing effect.

Start sealing

When the goods enter the sealing area, the fully automatic carton sealer will automatically perform the sealing action. The sealing device will stick the upper and lower tapes to the surface of the goods and heat-seal the tapes through the electric heating wire. After the heat sealing is completed, the device will automatically cut the tapes to complete the sealing process.

Collect the sealed goods

The sealed goods will continue to move along the conveyor belt and eventually be discharged from the equipment outlet. Please collect the sealed goods in time to avoid long-term accumulation on the equipment