Tengzhuo Packaging Machinery: A decade of expertise in high-performance vertical form fill seal (VFFS) machines. We deliver customized VFFS solutions with an expert engineering team, advanced production, and CE-certified quality. Benefit from tailored designs, continuous innovation, and reliable VFFS machinery to streamline your packaging and grow your business. Choose Tengzhuo for your vertical packaging needs.

Product Advantage

1. High-Speed and Stable Packaging Performance

Our vertical form fill seal machine is engineered for consistent, high-speed operation—achieving up to 80 bags per minute depending on the product and bag type. It ensures accurate filling and tight sealing, minimizing product waste. This high-efficiency system helps customers boost output and reduce labor costs, making it an ideal automatic packaging solution for growing production lines.

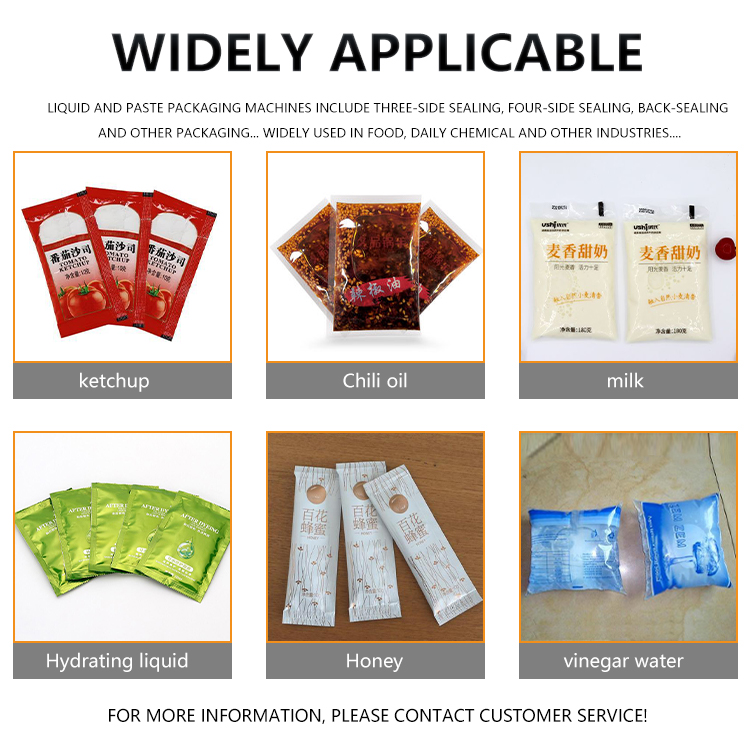

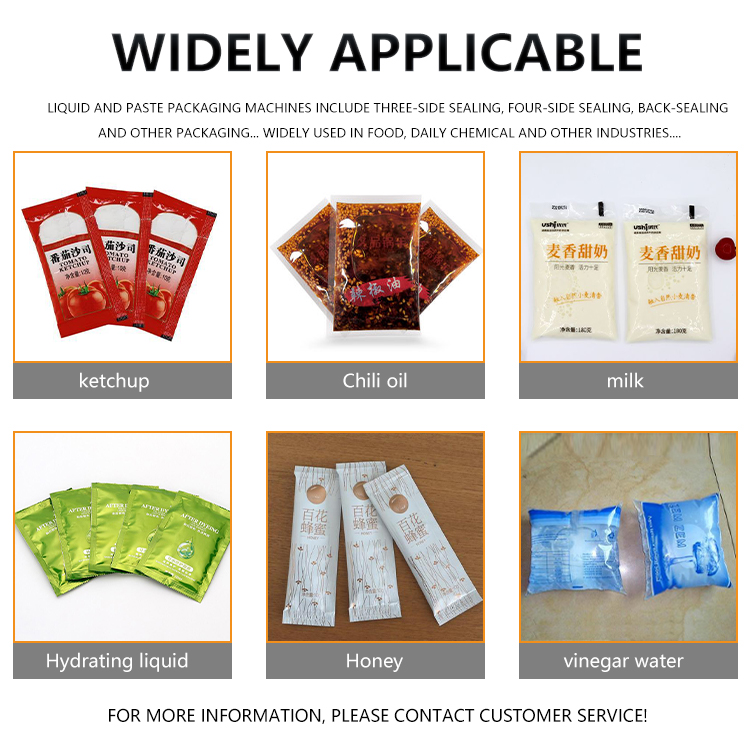

2. Versatile Packaging for Various Products

Whether you're packaging powders, granules, liquids, or pastes, this machine can handle it all. It supports a wide range of bag styles, such as pillow bags, gusseted bags, and flat-bottom bags. This flexibility makes it suitable for food, pharmaceutical, chemical, and hardware industries, ensuring seamless integration into different product lines.

3. Precision Control System

Equipped with an advanced PLC control system and touchscreen interface, the machine offers easy operation and real-time monitoring. It ensures precise control over bag length, filling volume, and sealing temperature—reducing downtime and enhancing the reliability of your high-speed pouch packing machine.

4. Durable Construction and Safety Features

Built with 304 stainless steel, the machine is corrosion-resistant and meets food-grade hygiene standards. It includes multiple safety sensors for automatic stop in case of film break, product misalignment, or open doors—ensuring safe and smooth operation during long production hours.

5. Space-Saving Vertical Design

The vertical form packaging machine has a compact footprint that fits easily into small to medium-sized production spaces. Its vertical layout simplifies film feeding and product filling, making it ideal for workshops where floor space is limited but production demands are high

Technical Parameters

Packaging film width: ≤220mm (can be customized according to actual size)

Bag making size: length 40-150mm, width 40-110mm

Sealing type: four-side sealing (can be customized back seal, three-side sealing, special-shaped bag, etc.)

Sealing texture: mesh (can be customized straight grain, pattern, etc.)

Power supply: 220V/380V/50Hz/60Hz/1350W

Machine weight: about 140KG

Packaging materials: composite film/composite paper/polyethylene, nylon/polyethylene, polyester/aluminum foil/polyethylene, tea filter paper, etc.

Machine size: Length, width and height 1100*804*1890 MM

Cutting knife type: flat knife (rounded knife, toothed knife can be customized)

Air consumption: 0.8Mpa 0.4m3/minute

Product Uses

1. Food Packaging

Ideal for packing rice, sugar, coffee, snacks, frozen foods, spices, and sauces, the vertical form fill seal machine ensures hygiene and extends shelf life. Its ability to handle solid, powder, and liquid products makes it a perfect fit for food processing lines looking for automatic packaging solutions that ensure consistent output and reduced manual handling.

2. Pharmaceuticals and Healthcare

This machine is used to package powders (like protein, supplement mixes), tablets, and small medical items. It offers high precision and cleanliness, which are critical for the pharmaceutical industry. With air-tight sealing and easy integration with dosing systems, it supports strict hygiene and quality control requirements.

3. Chemical and Industrial Products

In industries packaging fertilizers, detergents, or granular chemicals, the vertical packaging machine offers dust-free, moisture-proof sealing. It ensures worker safety and accurate dosages. Its rugged build supports heavy-duty cycles and maintains stable performance even with abrasive or fine particulate products.

4. Cosmetics and Personal Care

From facial masks and creams to bath salts and lotions, this machine handles various viscosities and product types with ease. Its clean sealing and high-speed operation help cosmetic brands meet large-volume packaging demands while preserving product integrity and aesthetics.

5. Hardware and Small Components

Perfect for nails, screws, washers, and other small industrial parts, the high-speed pouch packing machine ensures secure and organized packaging. It improves inventory management and helps in retail presentation. Automated counting and weighing systems can be integrated for maximum efficiency.

Product Operate Guide

Power On and Preheating

Connect the machine to the power supply and turn it on. Allow the machine to preheat, ensuring the sealing components reach the correct temperature for smooth operation.

Preparation

Load the roll film onto the film holder and prepare the packaging materials. Ensure the film is aligned correctly and that the product is ready for filling.

Parameter Settings

Set the required parameters on the control panel based on your product needs. Adjust the filling weight, bag length, and packaging speed to match the material and production requirements.

Material Loading

Fill the product into the hopper either manually or using an automatic feeding system such as a vacuum feeder. This ensures a continuous and steady supply to the machine.

Start Packaging

Press the start button. The vertical form fill seal machine will automatically complete the processes of bag forming, product filling, sealing, and cutting in a smooth, continuous cycle.