English

T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

| Availability: | |

|---|---|

| Quantity: | |

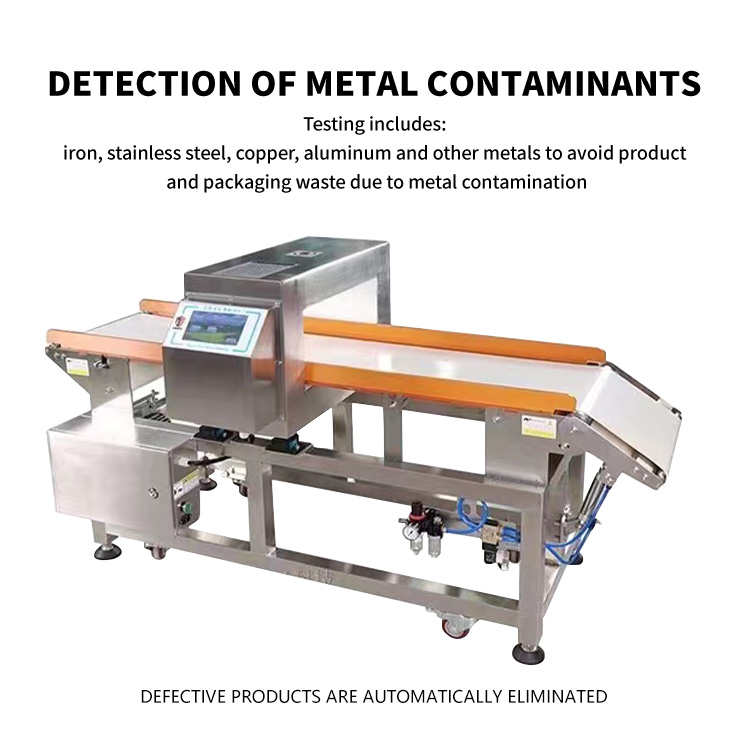

Product Advantage

High Efficiency

Metal detectors, including gold and silver testing machines, can inspect large quantities of products quickly, significantly enhancing production efficiency.

With a high degree of automation, the inspection process requires minimal manual intervention, further streamlining operations and saving time.

Accurate Detection

Utilizing advanced sensors and signal processing technology, metal detectors and metal analyzers can accurately detect metal impurities, such as trace amounts of ferrous and non-ferrous metals, in various products. This precision ensures consistent product quality and reliability.

Metal composition testing machines can also accurately identify specific metal types, including gold and silver, offering detailed insights into metal properties.

Safety Assurance

In industries like food, pharmaceuticals, and packaging, metal detectors play a critical role in identifying and eliminating metallic contaminants before they reach the consumer. This prevents accidents and ensures the safety and health of the public by protecting products from metal contamination.

Gold and silver testers help ensure the purity of precious metals, reducing the risk of fraud or safety issues in the jewelry and financial sectors.

Flexible and Versatile

Metal detectors and metal composition testing machines are designed to handle products of various shapes, sizes, and materials, making them adaptable to multiple industries, from manufacturing to food processing and even the precious metals market.

They support multiple inspection modes and customizable settings, allowing them to meet specific industry standards and inspection requirements.

Cost-Effective Operation

By automating the metal detection and analysis process, these machines help reduce labor costs, eliminate human errors, and minimize product recalls due to contamination.

Devices such as the metal analyzer and gold and silver testing machines provide comprehensive insights, reducing the need for expensive, time-consuming lab tests.

These advantages make metal checking machines, such as metal detectors, gold and silver testers, and metal analyzers, indispensable tools for industries prioritizing efficiency, accuracy, safety, and quality control.

Technical Parameters

Human-machine interface: LED digital display ,4.3-inch TFT touch screen, 7-inch TFT touch screen

Belt size 1200*300 mm

Channel height 100-150 (customizable)

Detection accuracy Iron 0.8, copper 1.0, stainless steel 2.0

Speed: 20-30 m/min

Detection method: Electromagnetic wave

Rejection method Push rod, air blowing, drop, alarm shutdown

Power supply: 220V, 50/60HZ

Product Uses

Food industry: Metal detectors are widely used in the food industry. They are mainly used to detect metal foreign bodies in a variety of products such as meat, fungi, candies, beverages, grains, fruits and vegetables, dairy products, aquatic products, health products, additives and condiments. Metal impurities mixed in food may cause harm to human health, so the use of metal detectors can accurately detect metal impurities in food and automatically remove them, thereby ensuring the safety and quality of food.

Pharmaceutical industry: In the pharmaceutical industry, metal detectors are mainly used to detect the metal content in medicines and health products. This helps to ensure the quality and safety of products and prevent product performance degradation or harm to the human body caused by metal impurities.

Chemical industry: In the chemical industry, metal detectors are used to detect the metal content in chemicals. Metal impurities mixed in chemical products may cause product performance degradation and even cause harm to the human body. Therefore, it is particularly important to use metal detectors for product testing.

Metallurgical industry: In the metallurgical industry, metal detectors are used to determine the composition of different batches of deoxidizers or return agents, as well as the testing of various materials.

Manufacturing: In the manufacturing industry, metal detectors are used to test semi-finished products or complete sets of parts to quickly find hidden problems in metal objects.

Electronics industry: In the electronics industry, metal detectors are mainly used for testing microwave radar parts, etc.

Product Operate Guide

Preparations

Before operating the metal detector, you need to prepare. First, check whether the power connection and circuit of the equipment are normal. Secondly, make sure that the key components of the equipment, such as the detection plate and sensor, are intact and not damaged or contaminated. Finally, make sure that the operating environment of the equipment is dry, sanitary, and free of dust and debris.

Start the equipment

Connect the power of the metal detector, turn on the power switch of the equipment, and the equipment starts.

Adjust the sensitivity of the equipment

Adjust the sensitivity of the equipment according to the characteristics and requirements of the product to be detected. Generally, the higher the sensitivity, the higher the detection accuracy, but it will also increase the detection time. The method of adjusting the sensitivity is usually to use the sensitivity adjuster on the equipment. Depending on the equipment, the adjuster may be a rotary button or a key. By adjusting the sensitivity, the equipment can detect foreign matter in the product more accurately.

Place the product

Place the product to be detected on the conveyor belt of the metal detector and ensure that the product passes completely through the detection plate area. The placement of the product should be evenly distributed, without stacking or squeezing.

Start the detection

Press the start button on the equipment and the metal detector starts to detect the product. The test results will be prompted by the display screen or sound signal on the device.

Classification and processing

According to the test results of the metal detector, the products containing foreign matter are classified and processed. For qualified products, they can continue to flow into the production line; for unqualified products, they should be eliminated, and the causes should be found and improved.

Cleaning equipment

After long-term use, the detection plate and sensor of the metal detector may be contaminated, affecting the detection accuracy. Therefore, the equipment needs to be cleaned regularly. The cleaning method can be determined according to the actual situation, such as wiping the sensor surface with alcohol cotton, or using a vacuum cleaner to clean the detection plate area.

Turn off the equipment

After completing the detection task, you need to turn off the power of the metal detector first, and then disconnect the power connection. At the same time, do a good job of equipment maintenance to ensure the good operation of the equipment.

In short, the operation of the metal detector needs to be carried out in accordance with certain steps, including preparation, adjustment of equipment sensitivity, placement of products, start of detection, classification, cleaning and shutdown of equipment. Only the correct operation method can ensure the detection accuracy of the equipment and extend the service life of the equipment.

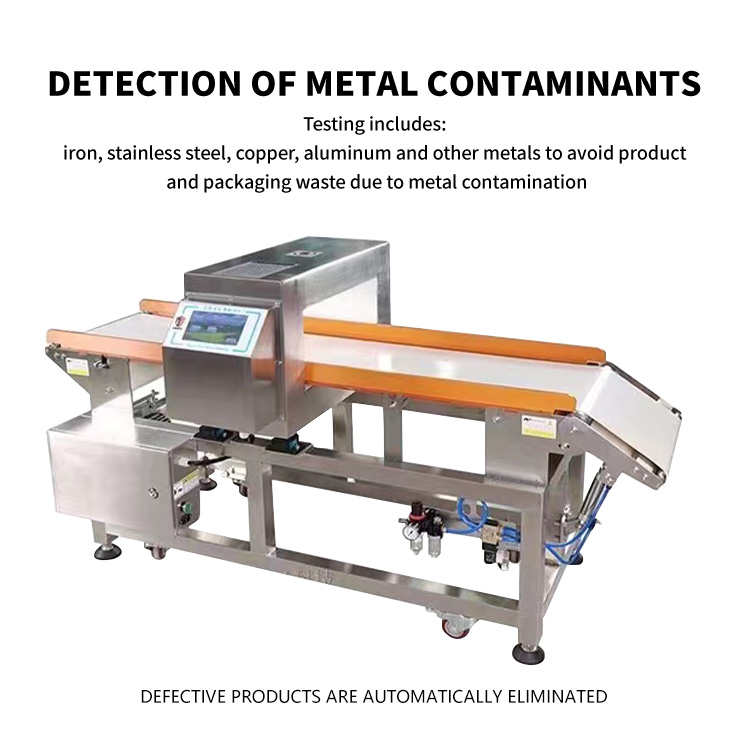

Product Advantage

High Efficiency

Metal detectors, including gold and silver testing machines, can inspect large quantities of products quickly, significantly enhancing production efficiency.

With a high degree of automation, the inspection process requires minimal manual intervention, further streamlining operations and saving time.

Accurate Detection

Utilizing advanced sensors and signal processing technology, metal detectors and metal analyzers can accurately detect metal impurities, such as trace amounts of ferrous and non-ferrous metals, in various products. This precision ensures consistent product quality and reliability.

Metal composition testing machines can also accurately identify specific metal types, including gold and silver, offering detailed insights into metal properties.

Safety Assurance

In industries like food, pharmaceuticals, and packaging, metal detectors play a critical role in identifying and eliminating metallic contaminants before they reach the consumer. This prevents accidents and ensures the safety and health of the public by protecting products from metal contamination.

Gold and silver testers help ensure the purity of precious metals, reducing the risk of fraud or safety issues in the jewelry and financial sectors.

Flexible and Versatile

Metal detectors and metal composition testing machines are designed to handle products of various shapes, sizes, and materials, making them adaptable to multiple industries, from manufacturing to food processing and even the precious metals market.

They support multiple inspection modes and customizable settings, allowing them to meet specific industry standards and inspection requirements.

Cost-Effective Operation

By automating the metal detection and analysis process, these machines help reduce labor costs, eliminate human errors, and minimize product recalls due to contamination.

Devices such as the metal analyzer and gold and silver testing machines provide comprehensive insights, reducing the need for expensive, time-consuming lab tests.

These advantages make metal checking machines, such as metal detectors, gold and silver testers, and metal analyzers, indispensable tools for industries prioritizing efficiency, accuracy, safety, and quality control.

Technical Parameters

Human-machine interface: LED digital display ,4.3-inch TFT touch screen, 7-inch TFT touch screen

Belt size 1200*300 mm

Channel height 100-150 (customizable)

Detection accuracy Iron 0.8, copper 1.0, stainless steel 2.0

Speed: 20-30 m/min

Detection method: Electromagnetic wave

Rejection method Push rod, air blowing, drop, alarm shutdown

Power supply: 220V, 50/60HZ

Product Uses

Food industry: Metal detectors are widely used in the food industry. They are mainly used to detect metal foreign bodies in a variety of products such as meat, fungi, candies, beverages, grains, fruits and vegetables, dairy products, aquatic products, health products, additives and condiments. Metal impurities mixed in food may cause harm to human health, so the use of metal detectors can accurately detect metal impurities in food and automatically remove them, thereby ensuring the safety and quality of food.

Pharmaceutical industry: In the pharmaceutical industry, metal detectors are mainly used to detect the metal content in medicines and health products. This helps to ensure the quality and safety of products and prevent product performance degradation or harm to the human body caused by metal impurities.

Chemical industry: In the chemical industry, metal detectors are used to detect the metal content in chemicals. Metal impurities mixed in chemical products may cause product performance degradation and even cause harm to the human body. Therefore, it is particularly important to use metal detectors for product testing.

Metallurgical industry: In the metallurgical industry, metal detectors are used to determine the composition of different batches of deoxidizers or return agents, as well as the testing of various materials.

Manufacturing: In the manufacturing industry, metal detectors are used to test semi-finished products or complete sets of parts to quickly find hidden problems in metal objects.

Electronics industry: In the electronics industry, metal detectors are mainly used for testing microwave radar parts, etc.

Product Operate Guide

Preparations

Before operating the metal detector, you need to prepare. First, check whether the power connection and circuit of the equipment are normal. Secondly, make sure that the key components of the equipment, such as the detection plate and sensor, are intact and not damaged or contaminated. Finally, make sure that the operating environment of the equipment is dry, sanitary, and free of dust and debris.

Start the equipment

Connect the power of the metal detector, turn on the power switch of the equipment, and the equipment starts.

Adjust the sensitivity of the equipment

Adjust the sensitivity of the equipment according to the characteristics and requirements of the product to be detected. Generally, the higher the sensitivity, the higher the detection accuracy, but it will also increase the detection time. The method of adjusting the sensitivity is usually to use the sensitivity adjuster on the equipment. Depending on the equipment, the adjuster may be a rotary button or a key. By adjusting the sensitivity, the equipment can detect foreign matter in the product more accurately.

Place the product

Place the product to be detected on the conveyor belt of the metal detector and ensure that the product passes completely through the detection plate area. The placement of the product should be evenly distributed, without stacking or squeezing.

Start the detection

Press the start button on the equipment and the metal detector starts to detect the product. The test results will be prompted by the display screen or sound signal on the device.

Classification and processing

According to the test results of the metal detector, the products containing foreign matter are classified and processed. For qualified products, they can continue to flow into the production line; for unqualified products, they should be eliminated, and the causes should be found and improved.

Cleaning equipment

After long-term use, the detection plate and sensor of the metal detector may be contaminated, affecting the detection accuracy. Therefore, the equipment needs to be cleaned regularly. The cleaning method can be determined according to the actual situation, such as wiping the sensor surface with alcohol cotton, or using a vacuum cleaner to clean the detection plate area.

Turn off the equipment

After completing the detection task, you need to turn off the power of the metal detector first, and then disconnect the power connection. At the same time, do a good job of equipment maintenance to ensure the good operation of the equipment.

In short, the operation of the metal detector needs to be carried out in accordance with certain steps, including preparation, adjustment of equipment sensitivity, placement of products, start of detection, classification, cleaning and shutdown of equipment. Only the correct operation method can ensure the detection accuracy of the equipment and extend the service life of the equipment.